What Is Crude Oil Electrostatic Desalting and Dehydration?

Crude oil electrostatic desalting and dehydration is a fundamental yet critical pretreatment process in petroleum refining. Its core purpose is not to “directly remove salt from the oil”, but rather to separate the water contained in crude oil, allowing the inorganic salts dissolved in the water to be discharged together with the aqueous phase.

During crude oil production, gathering, transportation, and storage, crude oil almost inevitably carries a certain amount of saline water. This salt water does not exist in the form of solid salt particles, but instead as extremely fine water droplets dispersed within the oil phase, forming a relatively stable oil–water emulsion system. It is precisely this dispersed state that makes efficient separation by gravity settling alone difficult under practical operating conditions.

If crude oil that has not undergone desalting and dehydration is fed directly into the atmospheric and vacuum distillation units, under high-temperature conditions, salts may decompose and generate corrosive media, causing severe corrosion to heat exchangers, columns, and pipelines, while also leading to fouling and blockage. These issues significantly shorten the operating cycle of the unit. Therefore, in modern refining processes, electrostatic desalting units are typically installed upstream of crude oil distillation as an essential and indispensable pretreatment step.

Overview of Crude Oil Electrostatic Desalting and Dehydration Methods

Crude oil desalting and dehydration does not rely on a single method alone. Early-stage or relatively simple installations once employed gravity settling, chemical demulsification, or purely thermal treatment. However, when handling crude oils with high salt content or highly stable emulsions, these methods often show limited efficiency and poor operational stability.

The essence of the electrostatic desalting process is an enhanced oil–water separation based on conventional separation principles. In an electrostatic desalter, water injection, heating, demulsification, and electric field action do not operate independently, but function as an integrated process system with strong synergistic effects:

- Water injection provides a transferable aqueous phase to carry salts out of the crude oil;

- Heating reduces crude oil viscosity, improving water droplet mobility and settling conditions;

- The electric field is the most critical intensification mechanism in the entire electrostatic desalting process;

Owing to its clear advantages in separation efficiency, adaptability to variations in crude oil properties, and continuous, stable operation, electrostatic desalting is widely adopted in modern refineries as the primary crude oil pretreatment method. Depending on crude oil characteristics, AC, DC, or combined AC/DC electric field configurations are selected.

Basic Principles of Crude Oil Electrostatic Desalting

1. Water Droplet Coalescence Mechanism (Electric Field Effect)

From a physical perspective, crude oil electrostatic desalting relies on the separation behavior of the oil–water two-phase system under an electric field. In crude oil, water exists in an emulsified state, with small droplet size and strong dispersion, making rapid separation difficult when relying solely on gravity.

After crude oil enters the electrostatic desalter, the dispersed water droplets in the oil phase undergo electrostatic induction and polarization under a high-voltage electric field. The polarized droplets generate mutual attractive forces within the electric field, allowing originally dispersed fine droplets to collide more easily and gradually coalesce into larger droplets.

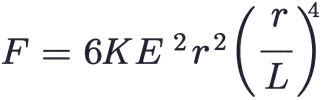

The coalescence force between water droplets can be expressed as:

- F: coalescence force between water droplets;

- K: a constant related to the properties of the medium;

- E: electric field strength;

- r: radius of the water droplet;

- L: center-to-center distance between water droplets;

As shown by the above relationship, the water droplet coalescence force is proportional to the square of the electric field strength, and is highly sensitive to droplet size and the spacing between droplets. This forms the theoretical basis for the significant enhancement of droplet coalescence through electric fields in electrostatic desalting units.

2. Water Droplet Settling Mechanism (Stokes’ Law)

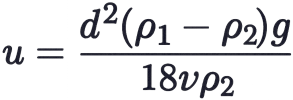

After water droplets gradually coalesce and grow under the action of the electric field, their effective separation from the oil phase ultimately depends on the settling velocity. The settling behavior of dispersed water droplets in the oil phase can generally be approximated using Stokes’ settling law:

- u: settling velocity of the water droplet (m/s);

- d: diameter of the water droplet (m);

- ρ1, ρ2: densities of water and oil, respectively (kg/m³);

- ν: kinematic viscosity of the oil (m²/s);

- g: gravitational acceleration (m/s²);

This relationship indicates that the primary ways to increase the settling velocity of water droplets include increasing droplet diameter, reducing oil-phase viscosity, and increasing the density difference between oil and water.

This is precisely the physical basis for improving desalting and dehydration efficiency in electrostatic desalting processes through heating to reduce viscosity and by enhancing water droplet coalescence.

3. Rational Selection of Electric Field Strength

It should be noted that the key to electrostatic desalting is not simply “the higher the voltage, the better.”

Although increasing electric field strength is beneficial to water droplet coalescence, under certain conditions it may also promote droplet dispersion. Moreover, desalting efficiency does not increase linearly with electric field strength. Beyond a certain range, further increases in voltage result in limited improvement in desalting performance.

Therefore, in practical engineering applications, greater emphasis is placed on the proper matching of electric field parameters with crude oil properties, temperature, wash water injection rate, and residence time, in order to achieve stable and controllable desalting and dehydration performance.

Typical Process Flow of Crude Oil Electrostatic Desalting

In engineering practice, crude oil electrostatic desalting is typically operated according to a relatively fixed process flow.

Crude oil is first heated by heat exchangers or a furnace to reduce viscosity and improve oil–water separation conditions. A certain proportion of wash water is then injected, allowing the salts contained in the crude oil to be fully transferred into the aqueous phase.

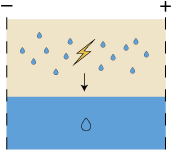

The mixed crude oil subsequently enters the electrostatic desalter vessel, where water droplet coalescence and settling separation are completed under the action of a high-voltage electric field. The separated saline wastewater is continuously discharged from the bottom of the vessel, while the desalted crude oil is withdrawn from the top and sent to downstream atmospheric and vacuum distillation units.

Although the process appears simple in form, its performance is highly dependent on proper control of operating parameters. Temperature, electric field strength, wash water injection rate, and residence time within the desalter vessel must be maintained in dynamic balance. Deviation of any single parameter from its optimal range will be directly reflected in fluctuations in desalting performance.